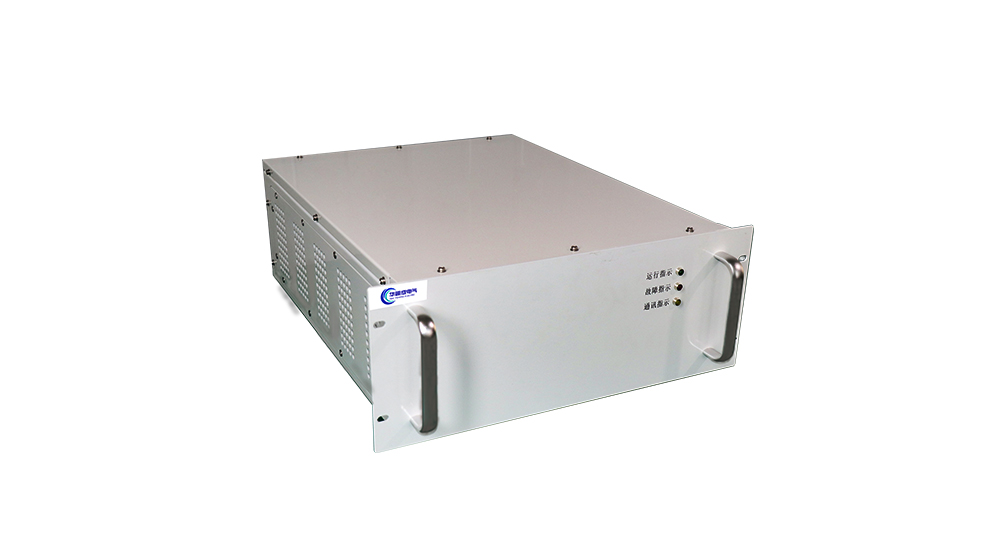

Electroplating electrolytic power supplyIt is an important industrial equipment that plays a vital role in the metallurgical industry. Through the use of electroplating electrolysis power supply, it can extract metals from ores or compounds, purify metals, and deposit metals from solutions. This kind of power supply It is a powerful method to promote oxidation and reduction reactions. Many oxidation and reduction reactions that are difficult to carry out can be completed by electroplating electrolytic power supply.

In terms of metal extraction, electroplating electrolytic power can extract metals from ores or compounds. For example, metallic sodium and chlorine are generated by electrolyzing molten sodium chloride. In this process, sodium chloride decomposes under the effect of an external electric field The aqueous solution of electrolyzed sodium chloride generates sodium hydroxide and chlorine gas, completing the extraction of metals.

In terms of metal purification, electroplating electrolysis power supply can deposit metals from the solution. For example, metal copper, zinc, lead, etc. are deposited from the solution, and the metal is purified through electrolytic deposition. In this process, DC power supply electrolysis It provides a powerful method to complete the difficult oxidation reduction reaction.

In addition to its use in metal extraction and purification, electroplating electrolytic power sources can also be used in many other aspects. For example, many non-ferrous metals (such as sodium, potassium, magnesium, aluminum, etc.) and rare metals (such as zirconium, hafnium, etc.) The refining of metals (such as copper, zinc, lead, etc.), the preparation of basic chemical products (such as hydrogen, oxygen, caustic soda, potassium chlorate, hydrogen peroxide, acetonitrile, etc.), as well as electroplating, electropolishing, anodizing, etc., are all It is completed through DC power electrolysis.

In short, electroplating electrolysis power supply plays an important role in the metallurgical industry. Through its use, many difficult oxidation and reduction reactions can be completed, making the extraction, purification and preparation of metals simpler and more efficient. At the same time, electroplating electrolysis power supply also It provides strong technical support for many other industrial fields. With the continuous improvement and development of technology, it is believed that electroplating and electrolysis power supplies will play a more important role in future industrial production.